Options to Replace a Concrete Driveway: Top Alternatives

A dirty, muddy, or broken pathway leading your guests from the street to your doorstep where your beautiful, warm, and welcoming home awaits them — don’t you find something wrong with this picture? Say the aforementioned driveway, for instance?

The fact that we groom our houses to match our personalities and then completely forget about the path leading up to it is unfortunate but true.

However, now that we are here and addressing it, why not explore some options to replace that broken driveway?

Let’s begin.

Top Alternatives To Replace Your Concrete Driveway

The following list is specially curated to index the top choices available when you want to replace your old and damaged pathway.

Gravel

Gravel isn’t just a common but highly preferred driveway material in many regions that experience exceedingly low temperatures. This is because while it looks beautiful all laid out and leading to your porch, it does not allow ice to build up on its surface. You may need additional gravel on the path during those snowy days, but it will nowhere be near as slick as the concrete might get.

Simultaneously, it is very economical and easy to install and can be purchased at any nearby home depot or gardening store. There is also little to no maintenance required with this material as compared to the existing concrete pathway you have.

Asphalt

A frequently used option in lieu of concrete is asphalt. It is similar to concrete in some ways but uses tar instead of cement as an adhesive, thus making it black in color and much rougher than concrete in both look and feel. It is cheap and quite simple to repair and maintain but has a shorter lifespan due to its tendency of cracking and splitting easily.

However, depending on the length of your driveway, it can actually turn out to be a good alternative to concrete.

Brick

Driveways made of brick are quite popular in a lot of circles due to the vivid personality they add to the house. With a lasting of over two decades, if installed and maintained properly, they come in a lot of color options that let you design the entire look. You can even match it with the exterior of your property for a put-together picture-perfect image.

On the other hand, the downsides to this kind of pathway are simply the time and money you’ll have to input for their construction and maintenance.

Rubber

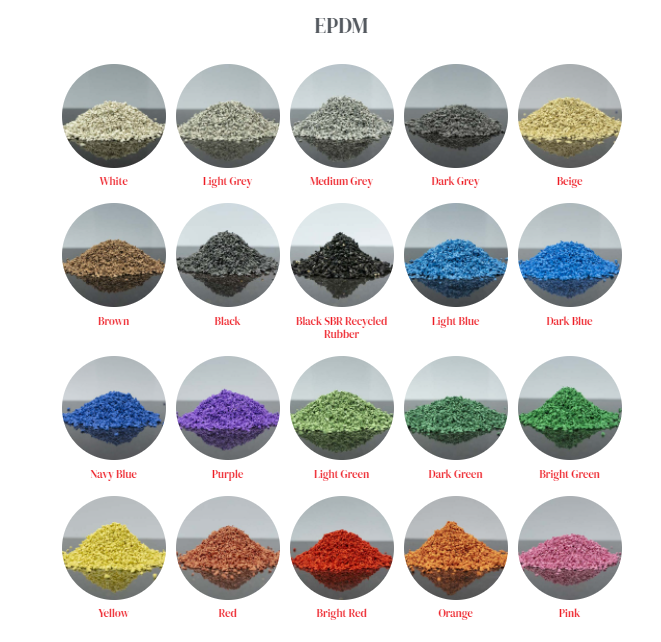

Yes, you read that right. Now, with the new innovations coming up, rubber surfacing can also be used to pave your driveway beautifully in as many as 40 colors. It can be easily installed above your existing concrete and/or asphalt pathway and is easy to maintain. It is durable and needs little maintenance over its lifespan to look as pretty as it did on day 1.

(Source)

Additionally, since the rubber used here comes from the tires and shoe soles that have already gone to waste, it ends up being great for the environment. Because this way, this rubber is not laying waste in landfills somewhere.

Timber

Timber, as you already know, comes from trees which makes it extremely eco-friendly right from the first stance. Simultaneously, this also lowers the prices attached to its acquisition and installation. Mixed with soil, sleepers, both new and recycled, can be laid out to present you with a beautiful driveway that has a rugged yet natural look. They need very little effort to be maintained over the years and even those fallen autumn leaves won’t make your pristine pathway look messy.

The only cons to this kind of driveway are that they are susceptible to both vermin and fire, and have a relatively shorter life than concrete.

Final Thoughts

A beautiful driveway is all you want in front of your equally gorgeous abode, and the concrete alternatives we shared above are sure to give you a lot to think about. Explore all your options well and we hope you make the choice best suitable for you and your residence.

Frequently Asked Questions

What are the eco-friendly options for paving a driveway?

There are several environmentally friendly options available today when it comes to paving a beautiful driveway. Timber, rubber, and mulch are some of the most preferred choices amongst them.

What is the most common surfacing option for a driveway?

Although the material for the driveway can vary a lot from place to place depending upon the region, climate conditions, and availability of materials, etc. But gravel has been found to be one of the most used alternatives across climatic and geographical barriers.

How to decide between repairing and replacing a concrete driveway?

The decision of whether your concrete driveway simply needs a fix-up or a complete replacement is a crucial one and depends extensively on the kind of damage your current pathway has suffered. However, if you are still unable to conclude what your next step should be, asking a professional surfacer for help might be your best option.